Isolasi Busa Karet NBR Sel Tertutup

Katrangan Produk

Metode uji standar rating geni sing ditindakake ing kahanan laboratorium sing dikontrol minangka ukuran materi kanggo nyebarake geni nalika dibandhingake karo standar sing dikenal lan ora dimaksudake kanggo nggambarake bebaya sing disebabake dening materi iki utawa materi apa wae ing kahanan geni sing nyata.

Dimensi Standar

| Dimensi Kingflex | |||||||

| Tkepincangan | Width 1m | Wjembaré 1.2m | Wjembaré 1,5m | ||||

| Inci | mm | Ukuran (P * L) | ㎡/Gulung | Ukuran (P * L) | ㎡/Gulung | Ukuran (P * L) | ㎡/Gulung |

| 1/4" | 6 | 30 × 1 | 30 | 30 × 1.2 | 36 | 30 × 1.5 | 45 |

| 3/8" | 10 | 20 × 1 | 20 | 20 × 1.2 | 24 | 20 × 1.5 | 30 |

| 1/2" | 13 | 15 × 1 | 15 | 15 × 1.2 | 18 | 15 × 1.5 | 22.5 |

| 3/4" | 19 | 10 × 1 | 10 | 10 × 1.2 | 12 | 10 × 1.5 | 15 |

| 1" | 25 | 8 × 1 | 8 | 8 × 1.2 | 9.6 | 8 × 1.5 | 12 |

| 1 1/4" | 32 | 6 × 1 | 6 | 6 × 1.2 | 7.2 | 6 × 1.5 | 9 |

| 1 1/2" | 40 | 5 × 1 | 5 | 5 × 1.2 | 6 | 5 × 1.5 | 7.5 |

| 2" | 50 | 4 × 1 | 4 | 4 × 1.2 | 4.8 | 4 × 1.5 | 6 |

Lembar Data Teknis

| Data Teknis Kingflex | |||

| Properti | Unit | Nilai | Metode Tes |

| Rentang suhu | °C | (-50 - 110) | GB/T 17794-1999 |

| Rentang kapadhetan | Kg/m3 | 45-65Kg/m3 | ASTM D1667 |

| Permeabilitas uap banyu | Kg/(mspa) | ≤0.91×10﹣¹³ | DIN 52 615 BS 4370 Part 2 1973 |

| μ | - | ≥10000 | |

| Konduktivitas Termal | W/(mk) | ≤0.030 (-20°C) | ASTM C 518 |

| ≤0.032 (0°C) | |||

| ≤0.036 (40°C) | |||

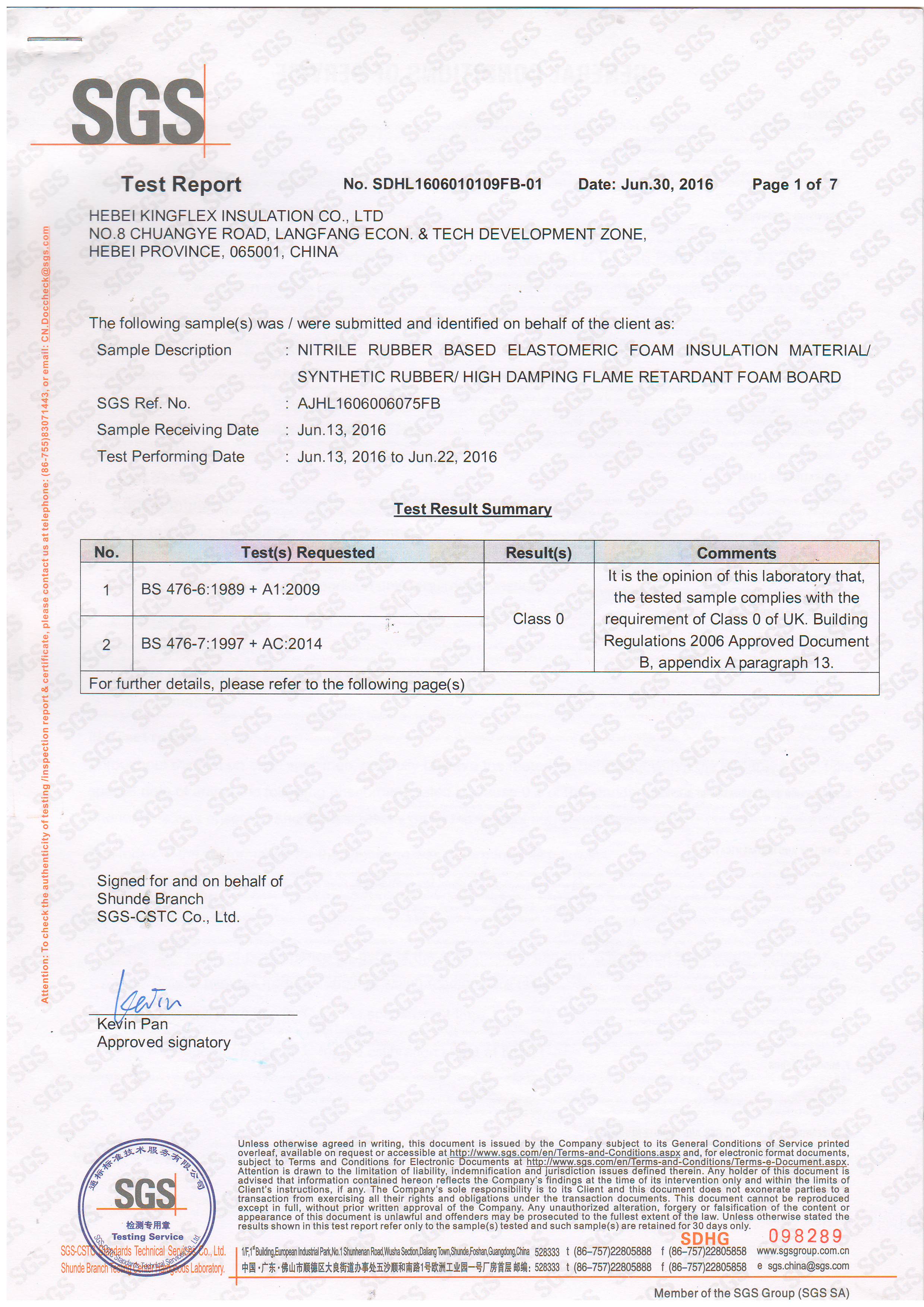

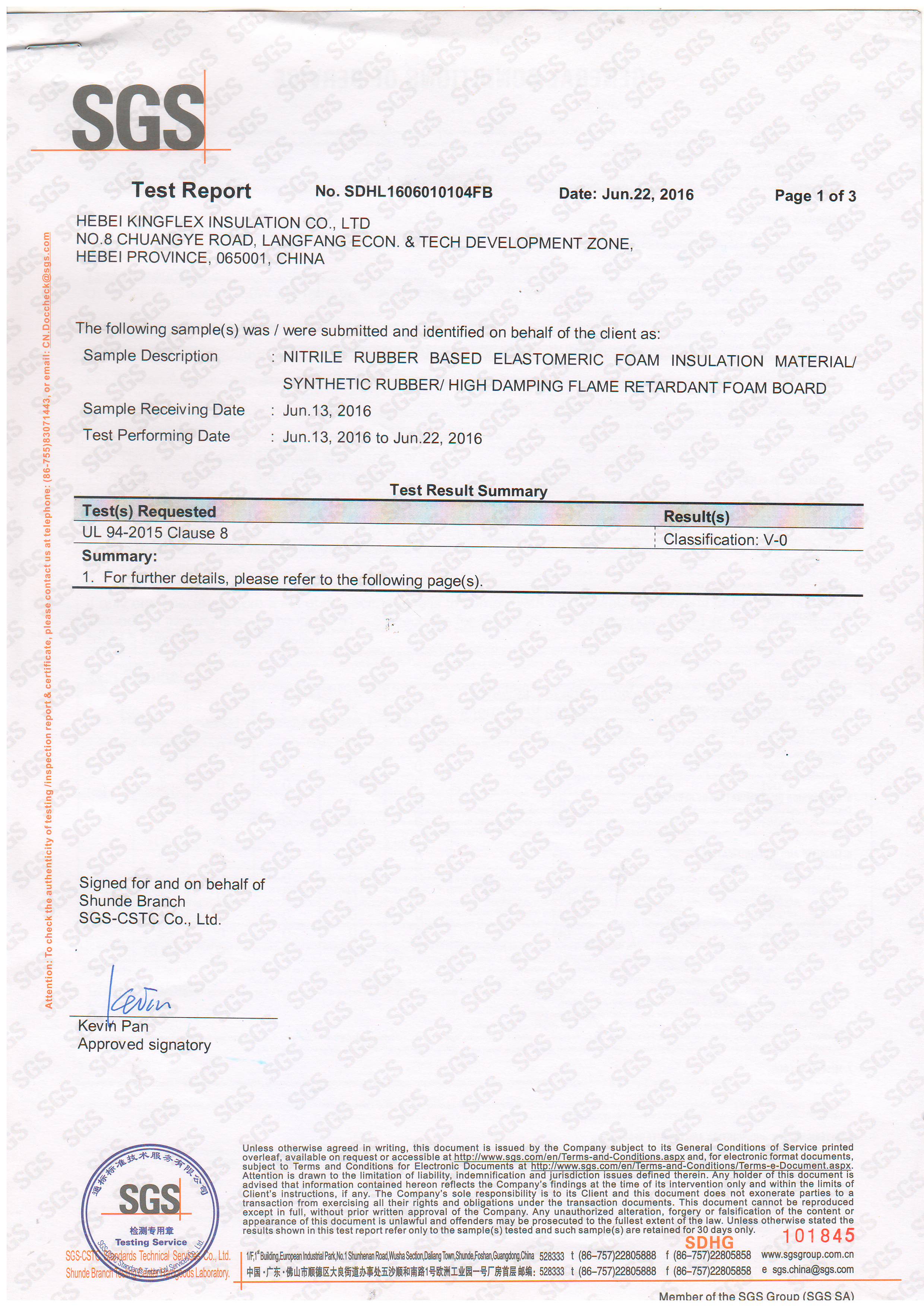

| Rating Kebakaran | - | Kelas 0 & Kelas 1 | BS 476 Bagian 6 bagian 7 |

| Indeks Penyebaran Api lan Asap sing Dikembangake | 25/50 | ASTM E 84 | |

| Indeks Oksigen | ≥36 | GB/T 2406, ISO4589 | |

| Penyerapan Banyu,% miturut Volume | % | 20% | ASTM C 209 |

| Stabilitas Dimensi | ≤5 | ASTM C534 | |

| Resistensi jamur | - | Apik | ASTM 21 |

| Resistensi ozon | Apik | GB/T 7762-1987 | |

| Tahan marang UV lan cuaca | Apik | ASTM G23 | |

Kauntungan Produk

♦ Fleksibilitas apik ing suhu endhek

♦ Resik, bebas bledug, instalasi cepet lan gampang

♦ Konduktivitas termal sing endhek

♦ Penampilan kualitas produk seragam sing apik

♦ Faktor tahan uap banyu sing dhuwur,>5500

Perusahaan Kita

Pameran Perusahaan

Sertifikat Perusahaan

Kategori produk

-

Telpon

-

Email

-

Whatsapp