Tabung insulasi busa karet Kingflex

Katrangan

Produk insulasi busa karet Kingflex iku maneka warna aplikasi. Karet sel cedhak ditemokake ing macem-macem produk. Industri otomotif: gasket entheng, sistem AC, dasbor, mesin. Industri bangunan: gasket, wedges. Industri sepur: bantalan sepur. Kelautan: gasket, proteksi geni, set kompresi rendah, emisi rendah. Elektronik: gasket, AC.

Lembar Data Teknis

| Data Teknis Kingflex | |||

| Properti | Unit | Nilai | Metode Tes |

| Rentang suhu | °C | (-50 - 110) | GB/T 17794-1999 |

| Rentang kapadhetan | Kg/m3 | 45-65Kg/m3 | ASTM D1667 |

| Permeabilitas uap banyu | Kg/(mspa) | ≤0.91×10 ﹣¹³ | DIN 52 615 BS 4370 Part 2 1973 |

| μ | - | ≥10000 | |

| Konduktivitas Termal | W/(mk) | ≤0.030 (-20°C) | ASTM C 518 |

| ≤0.032 (0°C) | |||

| ≤0.036 (40°C) | |||

| Rating Kebakaran | - | Kelas 0 & Kelas 1 | BS 476 Bagian 6 bagian 7 |

| Indeks Penyebaran Api lan Asap sing Dikembangake |

| 25/50 | ASTM E 84 |

| Indeks Oksigen |

| ≥36 | GB/T 2406, ISO4589 |

| Penyerapan Banyu,% miturut Volume | % | 20% | ASTM C 209 |

| Stabilitas Dimensi |

| ≤5 | ASTM C534 |

| Resistensi jamur | - | Apik | ASTM 21 |

| Resistensi ozon | Apik | GB/T 7762-1987 | |

| Tahan marang UV lan cuaca | Apik | ASTM G23 | |

Kauntungan produk

1. Struktur Sel Tertutup

2. Konduktivitas Pemanasan Rendah

3. Konduktivitas termal sing kurang, Efektif ngurangi kerugian termal

4. Tahan geni, kedap swara, fleksibel, elastis

5. Protektif, anti-tabrakan

6. Gampang, alus, ayu lan gampang dipasang

7. Aman kanggo lingkungan

8. Aplikasi: AC, sistem pipa, ruang studio, bengkel, bangunan, konstruksi, sistem HAVC.

9. Fungsi Mian: Nyegel, insulasi termal, anti-seismik, insulasi swara, pencegahan geni, insulasi, anti-statis, anti-penuaan, anti-aus, anti-kompresi

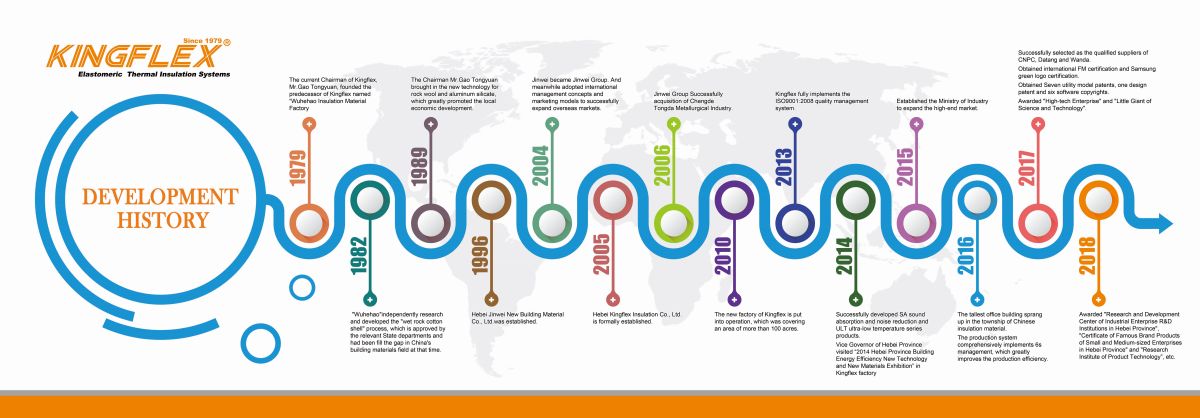

Perusahaan Kita

Pameran perusahaan

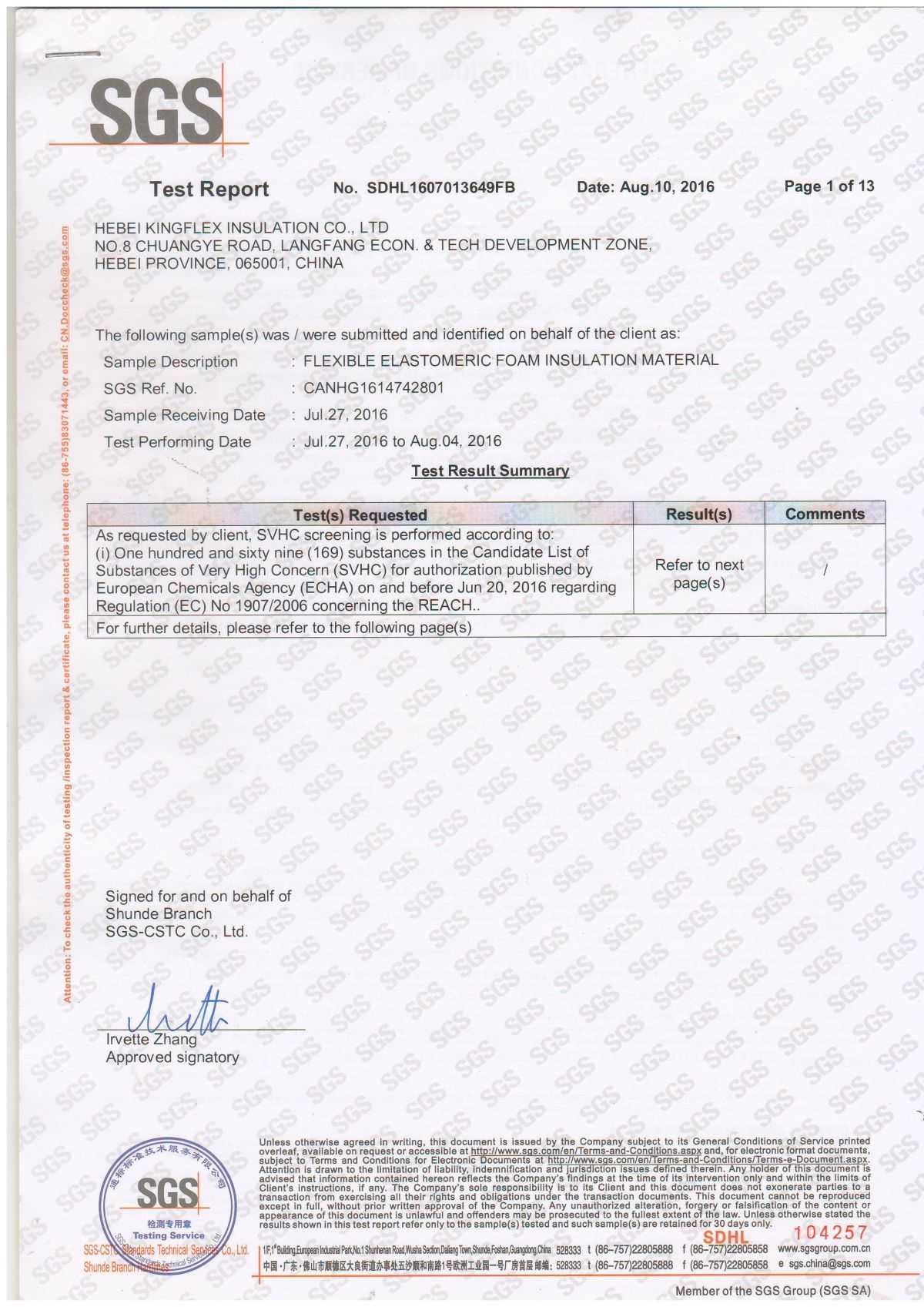

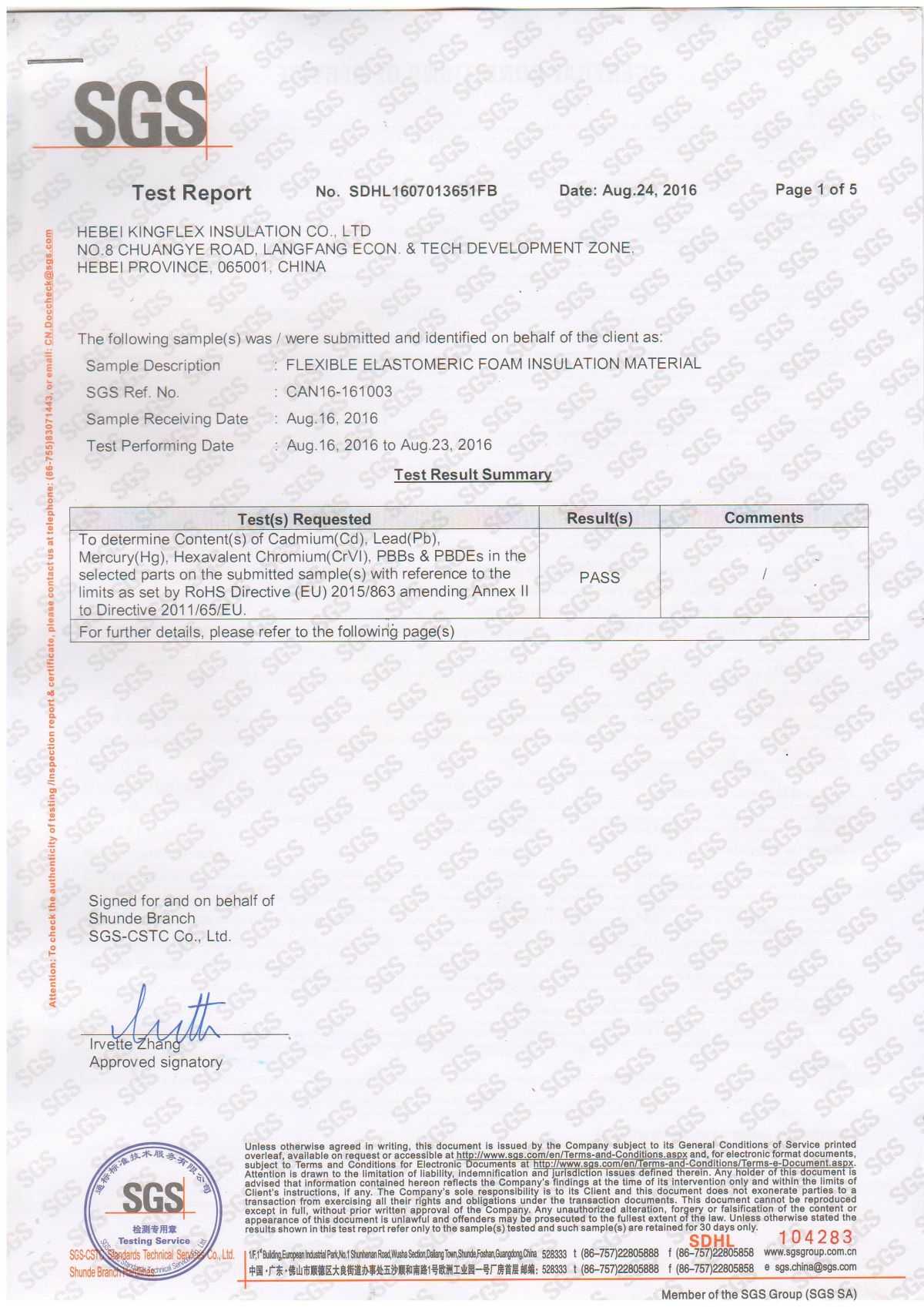

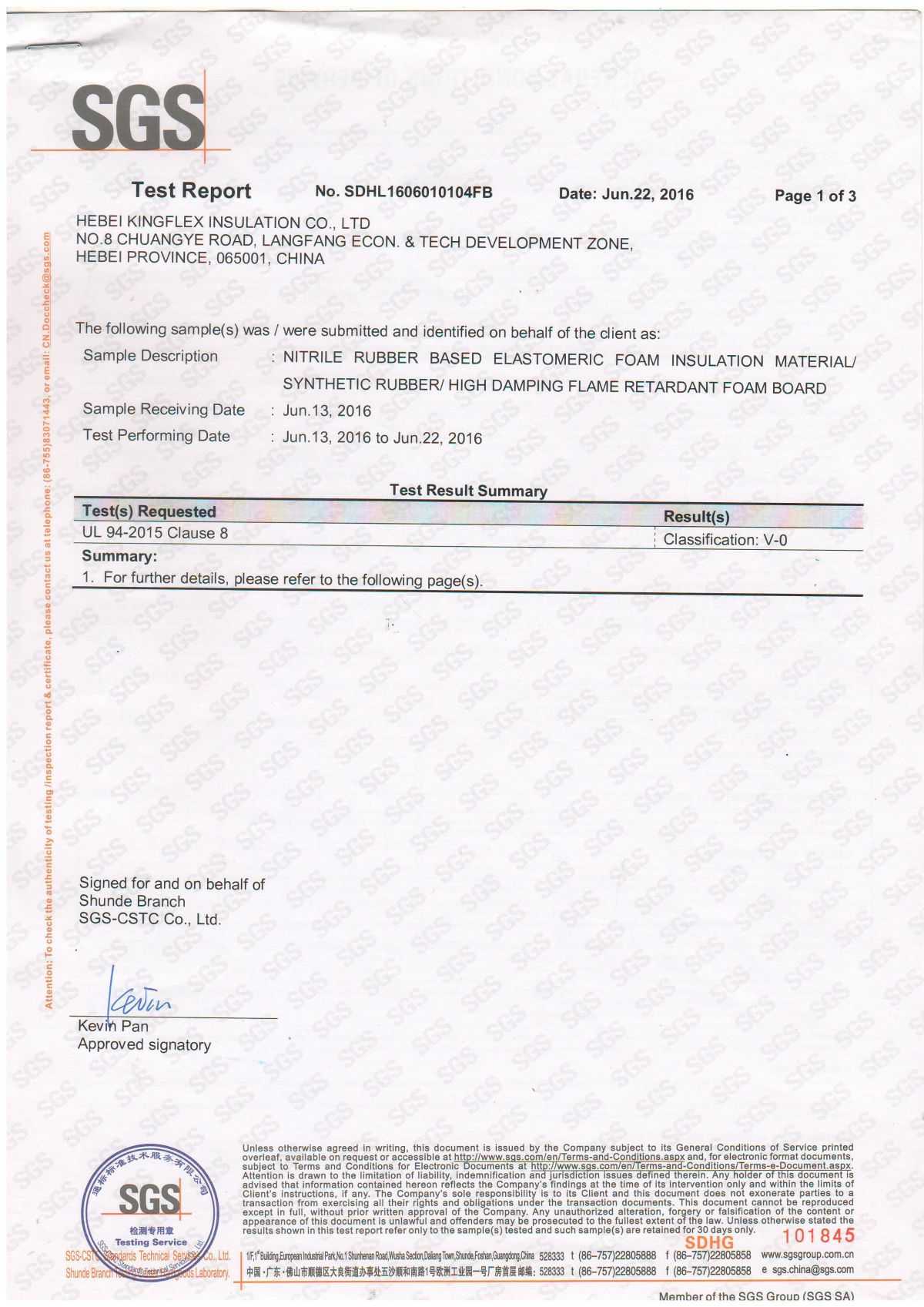

Sertifikat

Kategori produk

-

Telpon

-

Email

-

Whatsapp