LEMBAR INSULASI BUSA KARET PVC NBR

Katrangan Produk:

Produk iki bisa dilapisi nganggo macem-macem jinis foil (foil aluminium utawa kain kaca) lan nduweni lapisan perekat dhewe sing dipasang ing pabrik. Wektu instalasi luwih cepet saka 40% amarga gampang dipotong uga cepet nempel ing bahan kasebut.

Dimensi Standar

| Dimensi Kingflex | |||||||

| Tkepincangan | Width 1m | Wjembaré 1.2m | Wjembaré 1,5m | ||||

| Inci | mm | Ukuran (P * L) | ㎡/Gulung | Ukuran (P * L) | ㎡/Gulung | Ukuran (P * L) | ㎡/Gulung |

| 1/4" | 6 | 30 × 1 | 30 | 30 × 1.2 | 36 | 30 × 1.5 | 45 |

| 3/8" | 10 | 20 × 1 | 20 | 20 × 1.2 | 24 | 20 × 1.5 | 30 |

| 1/2" | 13 | 15 × 1 | 15 | 15 × 1.2 | 18 | 15 × 1.5 | 22.5 |

| 3/4" | 19 | 10 × 1 | 10 | 10 × 1.2 | 12 | 10 × 1.5 | 15 |

| 1" | 25 | 8 × 1 | 8 | 8 × 1.2 | 9.6 | 8 × 1.5 | 12 |

| 1 1/4" | 32 | 6 × 1 | 6 | 6 × 1.2 | 7.2 | 6 × 1.5 | 9 |

| 1 1/2" | 40 | 5 × 1 | 5 | 5 × 1.2 | 6 | 5 × 1.5 | 7.5 |

| 2" | 50 | 4 × 1 | 4 | 4 × 1.2 | 4.8 | 4 × 1.5 | 6 |

Lembar Data Teknis

| Data Teknis Kingflex | |||

| Properti | Unit | Nilai | Metode Tes |

| Rentang suhu | °C | (-50 - 110) | GB/T 17794-1999 |

| Rentang kapadhetan | Kg/m3 | 45-65Kg/m3 | ASTM D1667 |

| Permeabilitas uap banyu | Kg/(mspa) | ≤0.91×10﹣¹³ | DIN 52 615 BS 4370 Part 2 1973 |

| μ | - | ≥10000 | |

| Konduktivitas Termal | W/(mk) | ≤0.030 (-20°C) | ASTM C 518 |

|

|

| ≤0.032 (0°C) |

|

|

|

| ≤0.036 (40°C) |

|

| Rating Kebakaran | - | Kelas 0 & Kelas 1 | BS 476 Bagian 6 bagian 7 |

| Indeks Penyebaran Api lan Asap sing Dikembangake |

| 25/50 | ASTM E 84 |

| Indeks Oksigen |

| ≥36 | GB/T 2406, ISO4589 |

| Penyerapan Banyu,% miturut Volume | % | 20% | ASTM C 209 |

| Stabilitas Dimensi |

| ≤5 | ASTM C534 |

| Resistensi jamur | - | Apik | ASTM 21 |

| Resistensi ozon |

| Apik | GB/T 7762-1987 |

| Tahan marang UV lan cuaca |

| Apik | ASTM G23 |

Kauntungan produk

Kanggo nyegah kondensasi lan mbatesi mundhut energi ing ngendi pipa lan saluran, pendingin, lan peralatan AC dibutuhake.

Kanthi efisien nyuda aliran panas ing sistem panas, saluran, pipa gedhe, tangki, lan fitting.

Perusahaan Kita

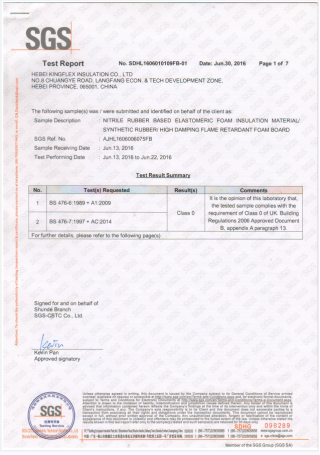

Sertifikat Perusahaan

Bagean saka Sertifikat kita

Kategori produk

-

Telpon

-

Email

-

Whatsapp