Lembaran Busa Karet PVC NBR

Katrangan

Bahan busa Kingflex Rubber yaiku bahan insulasi panas, pengawetan panas, lan konservasi energi sing alus sing digawe nganggo teknologi canggih ing njero negeri lan jalur produksi terus-menerus otomatis lengkap sing diimpor saka luar negeri, nggunakake karet butironitril kanthi kinerja paling apik lan polivinil Klorida (NBR, PVC) minangka bahan baku utama lan bahan bantu kualitas dhuwur liyane liwat proses pembusakan lan liya-liyane.

Dimensi Standar

| Dimensi Kingflex | |||||||

| Tkepincangan | Width 1m | Wjembaré 1.2m | Wjembaré 1,5m | ||||

| Inci | mm | Ukuran (P * L) | Gulungan | Ukuran (P * L) | Gulungan | Ukuran (P * L) | Gulungan |

| 1/4" | 6 | 30 × 1 | 30 | 30 × 1.2 | 36 | 30 × 1.5 | 45 |

| 3/8" | 10 | 20 × 1 | 20 | 20 × 1.2 | 24 | 20 × 1.5 | 30 |

| 1/2" | 13 | 15 × 1 | 15 | 15 × 1.2 | 18 | 15 × 1.5 | 22.5 |

| 3/4" | 19 | 10 × 1 | 10 | 10 × 1.2 | 12 | 10 × 1.5 | 15 |

| 1" | 25 | 8 × 1 | 8 | 8 × 1.2 | 9.6 | 8 × 1.5 | 12 |

| 1 1/4" | 32 | 6 × 1 | 6 | 6 × 1.2 | 7.2 | 6 × 1.5 | 9 |

| 1 1/2" | 40 | 5 × 1 | 5 | 5 × 1.2 | 6 | 5 × 1.5 | 7.5 |

| 2" | 50 | 4 × 1 | 4 | 4 × 1.2 | 4.8 | 4 × 1.5 | 6 |

Lembar Data Teknis

| Data Teknis Kingflex | |||

| Properti | Unit | Nilai | Metode Tes |

| Rentang suhu | °C | (-50 - 110) | GB/T 17794-1999 |

| Rentang kapadhetan | Kg/m3 | 45-65Kg/m3 | ASTM D1667 |

| Permeabilitas uap banyu | Kg/(mspa) | ≤0.91×10 ﹣¹³ | DIN 52 615 BS 4370 Part 2 1973 |

| μ | - | ≥10000 | |

| Konduktivitas Termal | W/(mk) | ≤0.030 (-20°C) | ASTM C 518 |

| ≤0.032 (0°C) | |||

| ≤0.036 (40°C) | |||

| Rating Kebakaran | - | Kelas 0 & Kelas 1 | BS 476 Bagian 6 bagian 7 |

| Indeks Penyebaran Api lan Asap sing Dikembangake |

| 25/50 | ASTM E 84 |

| Indeks Oksigen |

| ≥36 | GB/T 2406, ISO4589 |

| Penyerapan Banyu,% miturut Volume | % | 20% | ASTM C 209 |

| Stabilitas Dimensi |

| ≤5 | ASTM C534 |

| Resistensi jamur | - | Apik | ASTM 21 |

| Resistensi ozon | Apik | GB/T 7762-1987 | |

| Tahan marang UV lan cuaca | Apik | ASTM G23 | |

Kauntungan produk

1. Insulasi termal sing apik banget - konduktivitas termal sing sithik banget

2. Insulasi akustik sing apik banget - bisa nyuda gangguan lan transmisi swara

3. Tahan lembab, tahan geni

4. Kekuwatan sing apik kanggo nolak deformasi

5. Struktur sel tertutup

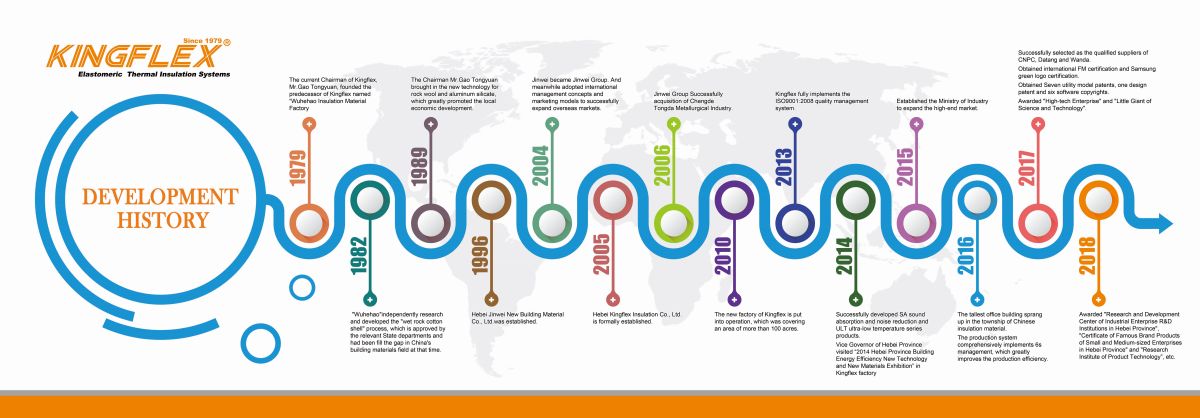

Perusahaan Kita

Pameran perusahaan

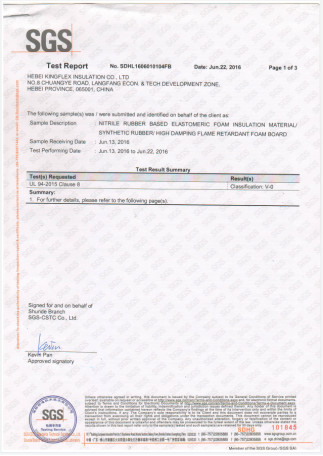

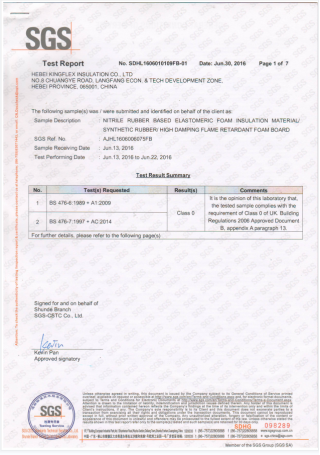

Bagean saka Sertifikat Kita

Kategori produk

-

Telpon

-

Email

-

Whatsapp